Elitron’s innovative and highly technological cutting systems are unique in that they all have a powerful vacuum, highly sectorised working area. This vacuum system guarantees that all materials are firmly held in place during cutting and milling, to produce the best quality finish for all materials, including the most critical. Divided into individual sectors, the vacuum power is concentrated only where the cutting head is working, in order to guarantee maximum hold.

An article of Sustainable Packaging News

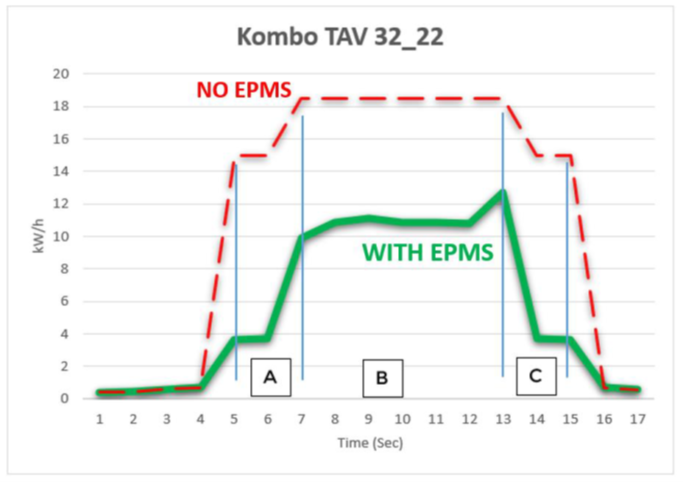

Elitron’s Power Management System – EPMS – is being installed in 2023 on Elitron’s Kombo range of cutting systems to reduce the energy consumption of this powerful vacuum, by up to 50%. It’s engineered using the electronic control board, designed entirely by Elitron, interfaced with the inverter, to manage a series of dedicated sensors, to optimize the operation of the vacuum motors. The electronic board ensures optimum vacuum power is used on the working area: it can either speed up or slow down the vacuum motor to ensure only the necessary vacuum power is used, and at the same time minimize the electric consumption. Simultaneously it monitors the maximum current absorbed by the motor, to guarantee continuous optimal working conditions. A compensation valve is used to constantly guarantee the required vacuum power, whilst maintaining the optimal working temperature of the vacuum motor even during intense workloads. SENSORS CONTROL: Vacuum sensor: continually measures the vacuum pressure on the working area, in order to guarantee that the correct vacuum pressure is used during the entire working session. Temperature sensor: measures the temperature of the vacuum motor, ensuring the optimal parameters are constantly maintained. The combination of these sensors guarantees maximum efficiency, and perfect working conditions for the vacuum pump, within an optimal value range. The EPMS also calibrates the temperature and vacuum probes, instantaneously reads the inverter status, and modifies the relative parameters. Specific parameters can be sampled during system operation, and it’s also possible to perform manual testing.

Compared to the traditional way of using a vacuum motor or a normal inverter, with EPMS there are notable energy savings. EPMS ensures the motor is only used as necessary and is continually operating within its maximum efficiency curve. In addition, there is a significant reduction in the level of wear on the system, as it is subject to far less stress. Using the rotation speed of the motor, the EPMS demonstrates excellent vacuum performance during processing; with the motor and all mechanical parts being used to the minimum.