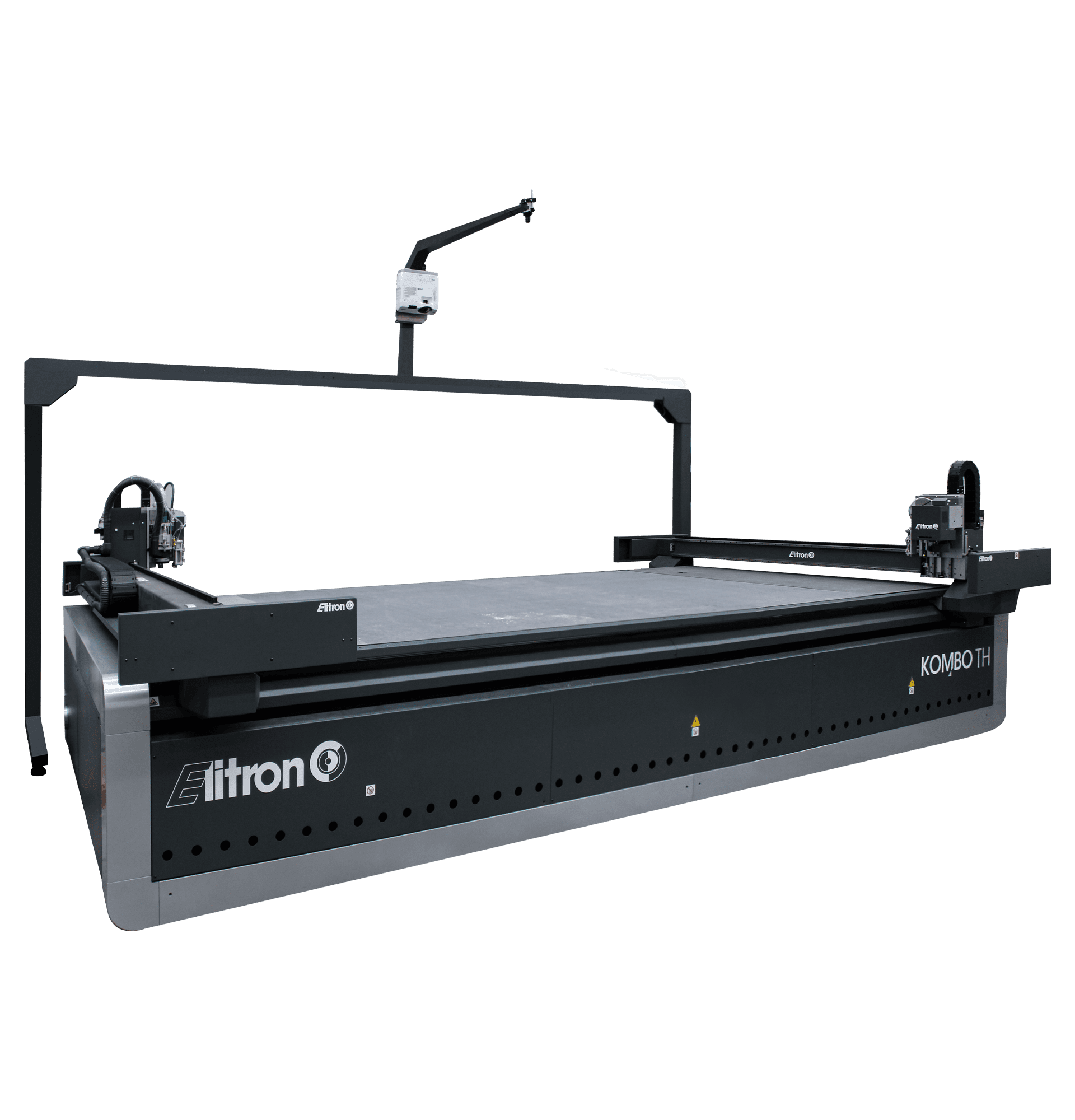

Automatic Cutting Solution with 2 Cutting Heads

Kombo TH / THC is the flatbad or conveyor digital cutting solution with double independent beam designed for those who must cope with great production workloads and demand top cutting performances. An automatic cutting plotter specifically engineered to meet the new requirements in the digital printing, cardboard, sign and billboard industries. This system with the powerful 3kW Milling Module, can be equipped with the new 7-position Automatic Tool Changer, designed for milling many different materials: plastics, aluminium, sponges, composites and more…

getting now to a total of 14 milling tools preinstalled and all automatically interchangeable!

Limitless creative possibilities for packaging and visual communications: POS displays, transparent containers, publicity banners, folders, files, boxes, embossed logos, trade fair stand panels, promotional flags, brochure holders, and many more.

Processes a wide range of materials with extreme precision (printed or not) like: forex, dibond, PVC, plastics, films, textiles, reboard, paper and cardboard, corrugated cardboard, foams.

Our team of consultants is at your disposal to offer you professional support in choosing the best solution for your company.