Maximum efficiency in double-sided printing

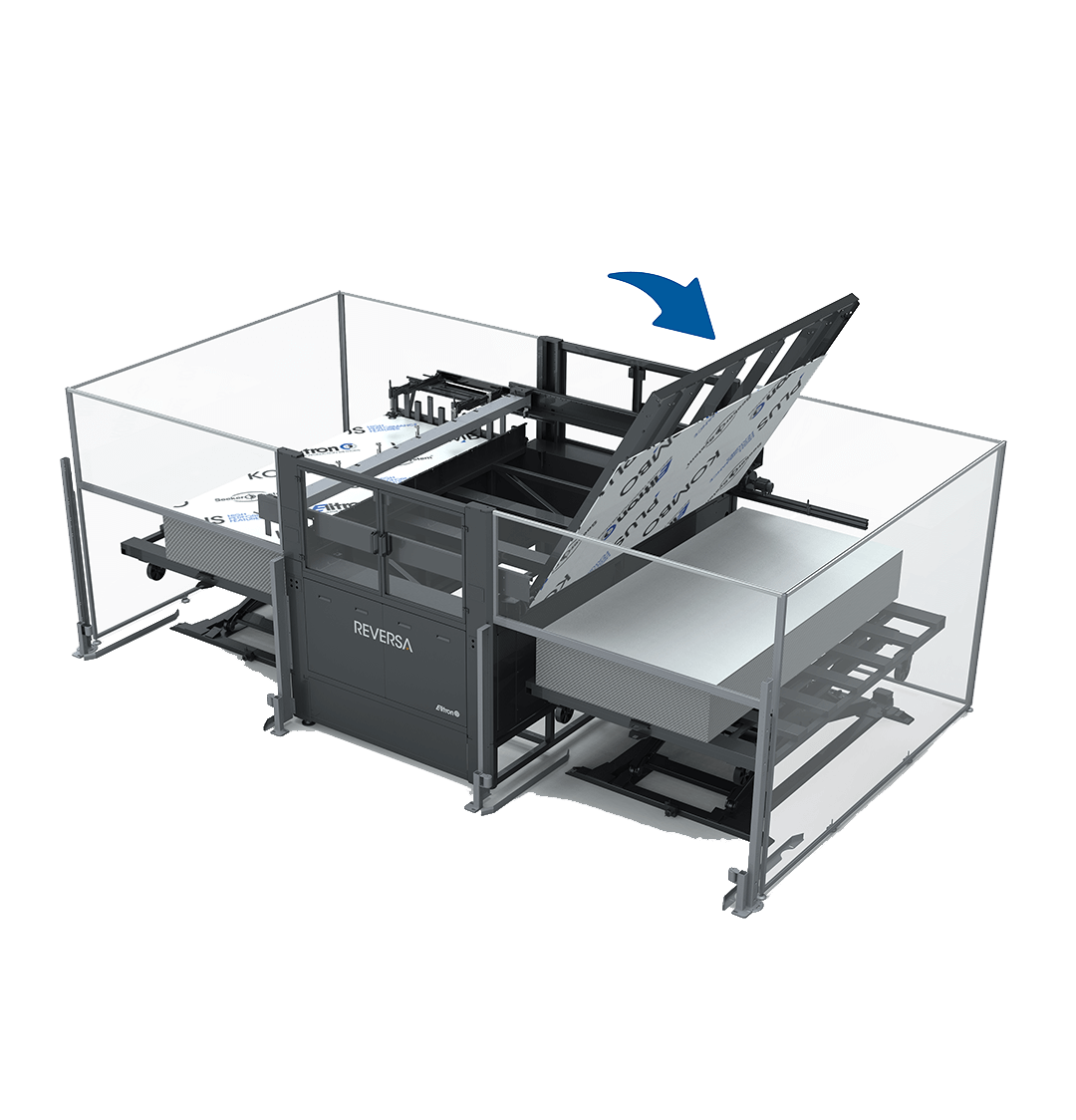

Reversa is a system that allows to overturn the printed processing after printing. In the case of two-sides printing, it is also possible to turn over the sheets already printed to facilitate the printing of the second side.

The system is provided in two ways: stand-alone and integrated.

Take your printing to a new level with REVERSA!

Reversa Stand -alone

The system allows to process pallets sequentially, independently of the other processes.

Maximum loading height:

Reversa Integrated

The system is an integrated part of the production line, it intervenes only on the pallets to be processed and guarantees operational continuity, including the transit of the empty pallet from the loading to the unloading.

Maximum loading height:

The suction cup and bellows system is programmable in relation to different requirements and guarantees the separation of the sheets even in presence of critical materials. Sensors also detect the exact position of the sheets and realign them if necessary. REVERSA can easily be configured to receive and return sheets on both sides of the pallet. Depending on the type of printer, either configuration 1 or 2 will be chosen.

Our team of consultants is at your disposal to offer you professional support in choosing the best solution for your company.